news&blog

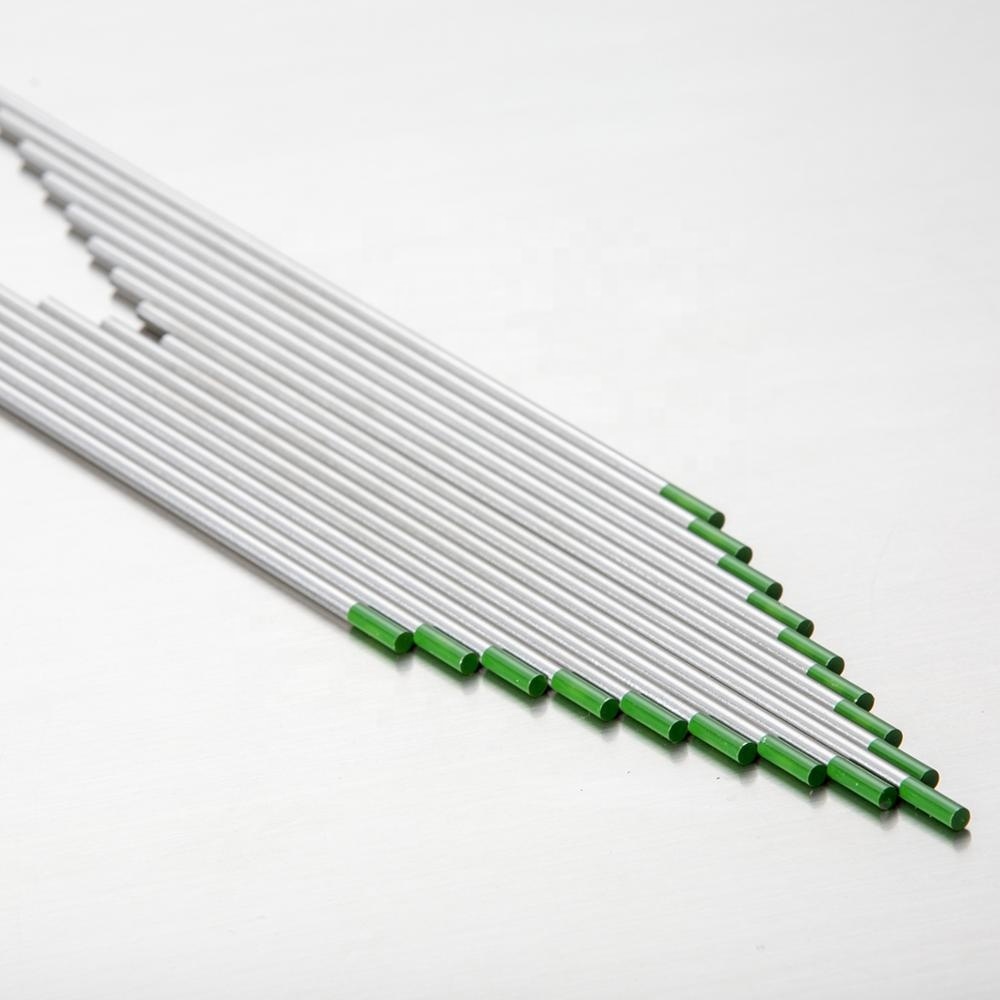

Classification of tungsten arc welding

2022-02-10

Tungsten arc welding can be divided into two kinds of manual tungsten arc welding and mechanized welding according to the operation method. For straight line weld and regular curve weld, mechanized welding can be used.

Tungsten arc welding can be divided into two kinds of manual tungsten arc welding and mechanized welding according to the operation method. For straight line weld and regular curve weld, mechanized welding can be used. For irregular or shorter welds, the use of manual tungsten arc welding. The more widely used is DC manual tungsten arc welding, DC tungsten arc welding is usually divided into two types:

DC reverse polarity

In tungsten tungsten arc welding, although rarely used DC reverse polarity, however, it has a kind of removal of oxide film effect. The so-called removal of oxide film effect, in the AC welding of the reverse polarity half-wave also exists, it is an important factor in the successful welding of aluminum, magnesium and its alloys. Aluminum, magnesium and its alloys, there is a layer of dense, refractory oxide film covering the surface of the weld pool, such as timely removal, the welding will result in the non-fusion, the surface of the weld will also form a wrinkled skin or produce porosity, slag, directly affecting the quality of welding. Practice has proved that the reverse polarity, the oxidized film on the surface of the welded metal under the action of the arc, can be removed to obtain a beautifully shaped weld. This role requires the cathode spot energy density to be very high and by the quality of a large positive ion impact, resulting in a broken oxide film.

DC Positive Polarity

When DC positive polarity, the weldment is connected to the positive pole, the weldment receives all the kinetic energy and escape work released by electron bombardment, and produces a lot of heat, so the molten pool is deep and narrow, the productivity is high, and the shrinkage and deformation of the weldment are small. When using DC positive polarity, tungsten electrode is the cathode, tungsten electrode melting point is high, at high temperatures when the electron emission ability is strong, the arc combustion stability is good. In addition to welding aluminum, magnesium and its alloys, generally use DC positive polarity connection method for welding.